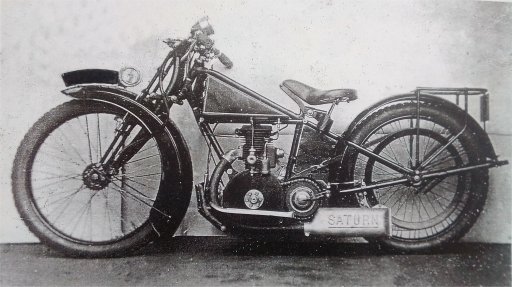

Saturn

Engine details as listed by factory:

Capacity: 350 cc

Type: Patented and improved two stroke cycle

Cooling: Air (thermo-syphon for stationary engines)

Bore: 78 mm

Stroke: 72 mm

Power: 3 hp at 1600 rpm when used in stationary set-ups e.g. saw bench, lighting plant etc. No separate spec survives for motorcycle use.

Crankshaft and piston rod: High grade steel, case hardened and ground

Bearings: Phosphor bronze, amply sized

Piston: Special close grained piston iron broached to fit splined end of piston rod to which it is firmly attached to make one unit

Lubrication: Mechanical oil pump driven from crankshaft

Ignition: H.T. Magneto driven by chain

Carburettor: Claudel Hobson or other approved English make (C.H. being aero engine carburettor manufacturers of some repute)

Description:

Simplicity of design, excellence of workmanship, and strict interchangeability are the outstanding features.

The engine runs on a patented and improved 2 stroke cycle, in which the the number of working parts has been reduced to a minimum.

In the ordinary three port type of two stroke engine the elimination of sleeves, valves, and tappets (as used in 4 cycle engines) is generally accompanied by an increase in fuel consumption and defective lubrication, resulting from crankcase compression.

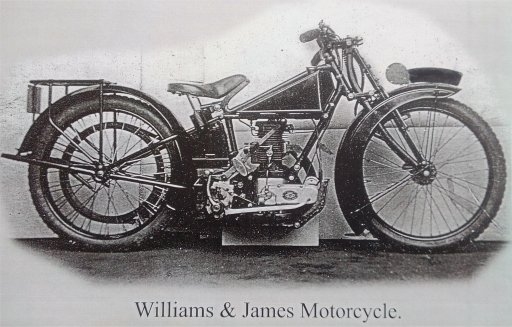

The W&J engine provides four cycle economy and efficiency with two stroke simplicity without the need for valves or other working parts. This makes it the ideal engine where reliability and silence is required.

The W&J engine runs equally on petrol or kerosene with the fuel consumption approx 0.9 pints per bhp hour (estimated to be over 100 mpg on the Saturn)

At this time W&J were busy experimenting in various fields trying to expand their production post WW1. They eventually chose air compressors to focus on and did not proceed beyond the small batch of air cooled motorcycle engines and water cooled stationary engines in 1925/26. The motorcycle used all proprietary parts outside of the engine, as could be expected for such a small volume production run. Sadly all drawings and production records were destroyed about 70 years ago. I did manage to speak to a retired ex-employee about 40 years back who could remember seeing the engine moulds lying in the stores, probably when he first started there.